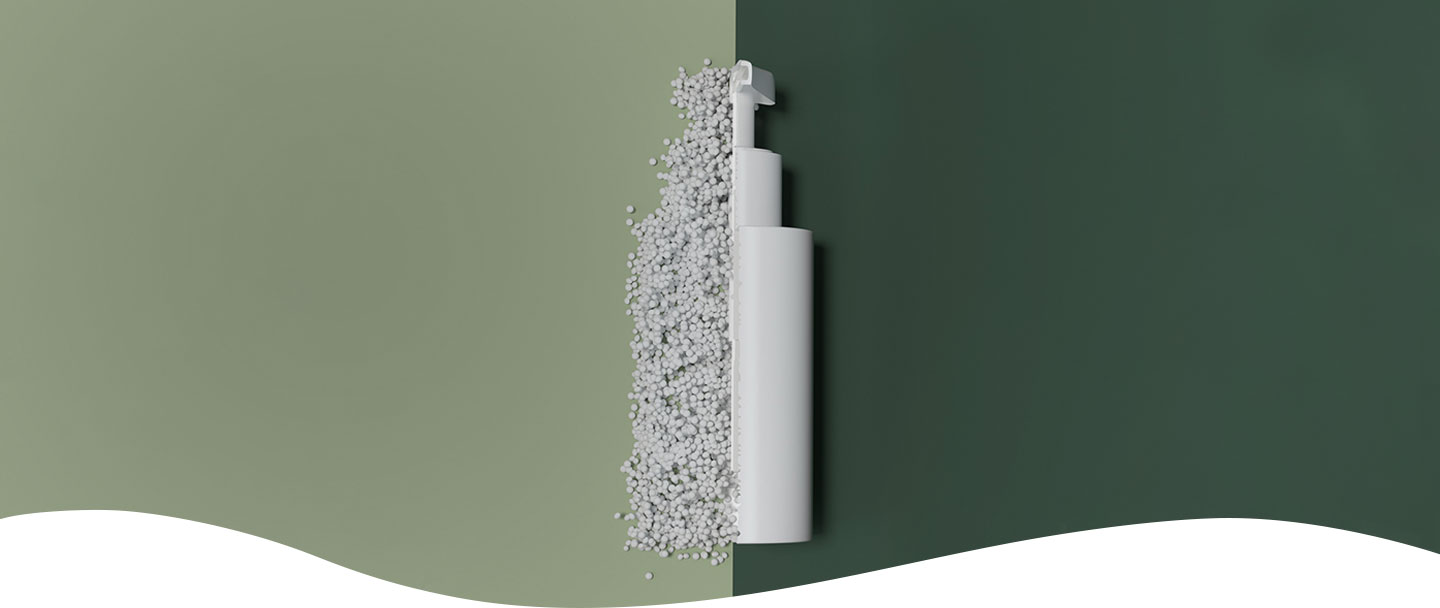

And now, mono material pump will change this situation. Using the same material for all the components, the pump is able to adapt to mainstream plastic recycling processes.

‘Pump can’t be recycled’ is becoming a recognised problem in market

The main stream plastic recycling process starts by shredding the plastic components into chips, washing the chips, and then turning them into renewed resin. Most basic containers made from recyclable materials can be recycled in this way such as shampoo bottles and cream jars. However, pumps or bioplastic cosmetic packaging with a pump mechanism can’t be recycled like this, as they contain metal springs and glass balls, which can block the recycling machines.

In order to recycle a pump, consumers have to break the pump by themselves to remove metal spring and glass ball as below picture, which is difficult and tiresome. Otherwise, recycling facility will sort the pumps out for burning or landfill.

Mono material pump, recyclable without breaking and disassembling.

To adapt the pumps to the recycling stream, mono-material pump is innovated. As its name suggested, recyclable lotion pumps have all its components made from PE plastic material, including the spring and the ball. In this way, plastic pump can be handled by the recycling machine just like custom printed cosmetic bottles and mono material jar. No more needs for breaking and disassembling.

Enhanced recyclability, no guilt on sustainable issue

When consumers finish using the product and plan to discard the packaging, the mono material pump will certainly be recycled. Your consumers won’t feel guilty for sustainability issue when choosing your brand again for their next purchase decision.

High durability ensures stable performance for repeated use

The availability of recyclable pump does not mean encouraging consumers to use them on a one-time basis. Actually, the quality of mono material pump is comparable to that of the normal metal pump. As the result of years of development and great investment, the mono material pump is meticulous designed for long-term stable use. Its dispensing durability is no less than around 3000+ times cycles, capable for finish using 1L refill pouches 6 times and equivalent to a normal metal pump.

Standard neck finish, free to match with bottles

The mono material pump has standard neck finish, applicable for a wide range of bottles in our stock packs, other bottles on the market, or the bottles you are currently using. Moreover, if the bottle is made from the same PE material, then you can call it a mono-material pack.

Endless customisation possibilities available

The colour of all external components, that is, the pump head, stem and collar can be customised. UA also has tooling workshop that supports customised shapes and logo designs. You can add your creativity to the design of your pump to establish a unique brand image and showcase your brand personality and style.

Parameters of UA mono-material pump

Open: Twist open

Material: Mono material PE

Neck finish: 28 (300-500ml bottle) and 33 (500-1L bottle)

Output: 2 and 4ml

Lifespan: no less than 3000 pumps

UA Packaging wholesale cosmetic packaging supplier shares: "To achieve eco-friendly, we will not stop here. In the future, we will continue to expand and improve our eco-solutions, such as PCR, OBP, paper-made, refillable cosmetic containers, metal-free, and so on. Check our catalogue for more information at https://linktr.ee/uapackaging If you have any ideas in mind, contact us to discover a fast custom-made solution at hello@uapkg.com"

Contact Us

Contact Us (1).webp)

_20250428095135.webp)

English

English  français

français  Español

Español  italiano

italiano