Refillable glass jar whose cap, disc and recharger are made from recyclable PP plastic and can be separated easilyafter use. Color of all components are customized, also kinds of deco like print, matt finish, gradeint deco is available here.

Feel bored in checking models?

We gonna help you find matched one fast

- Bottle

- Jar

- Tube

- Airless

- Dropper

- Deodorant Stick

- Glass

- Pump

- Sprayer

- Browse All

Refillable airless in glass

Glass is also great alternative to replace plastic shell and its thick wall provides luxury look and heavy feeling. Comparing with aluminum, glass has more customization possibilities because of full transparency character.

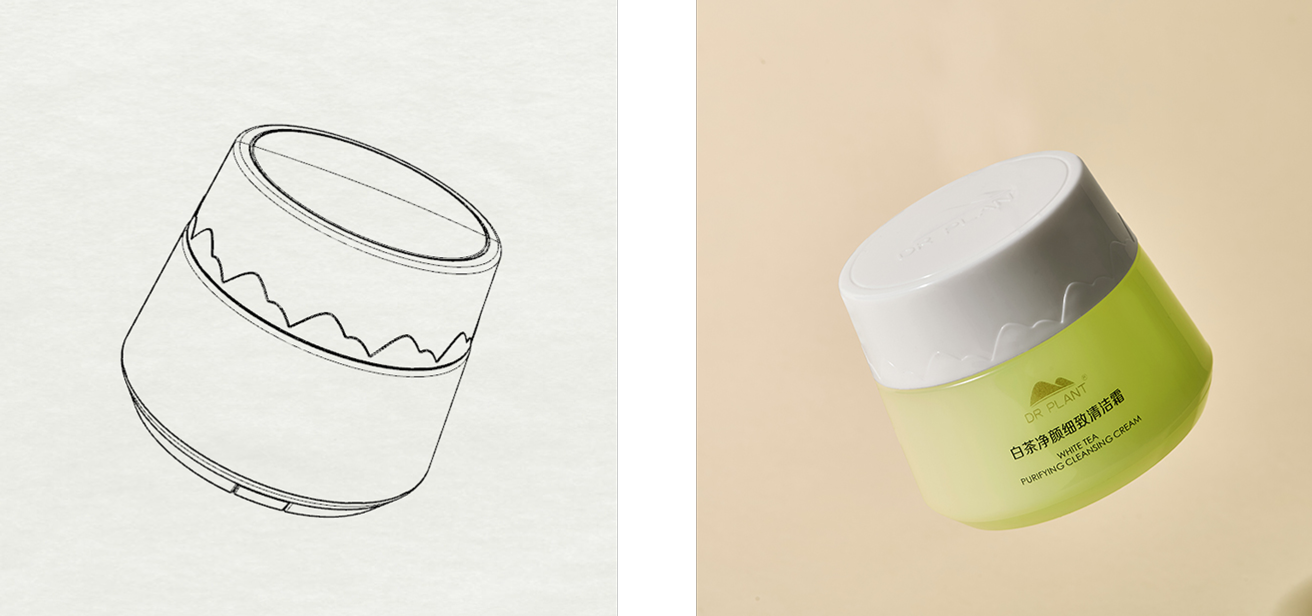

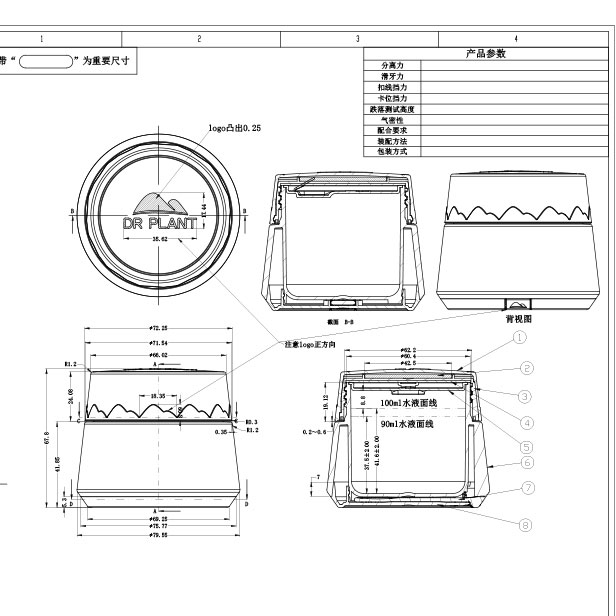

Macaron pack

Shape designed by UA features cute and playful impression and it goona be easier to attract young generation consumer than common model.

Color of all components including reducer tip, inner, outer cap and bottle can be customized.

Match products: sunscreen, foundation…

Sustainability: PCR

Volume size: 50ml(1.66oz)

ALU airless series- Airless bottle

Replacing material of outer shell from plastic to aluminum to achieve 50% plastic reduction and aluminum is most welcomed recyclable material in worldwide.

Color of all components including pump and aluminum part can be customized

Match products: face cream, sunscreen, hair treatment…

Sustainability: 50% plastic reduction, refillable design, endless recycling aluminum

Volume size: 30/50ml(1/1.66oz)

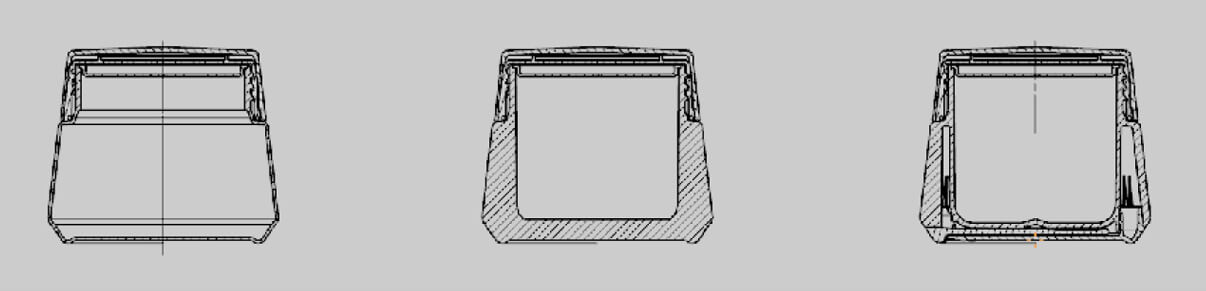

Easy-to-use spatula cream jar

Compelling advantage of this model is spatula in cap and you choose tweezer to replace spatula for mask, wipe pad product.

Color of all components including cap and jar can be customized

Jar supports Bi injection to achieve rich layered design.

Versatile use for all cream products

Sustainability: 100% recyclable mono material, PCR

Volume size: 50. 100ml(1.66, 3.33oz)

Bottle designed for waterless powder product

Unlike the baby powder bottle found in the supermarket, UA’s powder bottle has a more stylish appearance and delivers more aesthetic appeal. The slim shape makes the bottle more delicate and premium, elevating the product and the brand.

Versatile use for cleanser powder, exfoliator powder, dry shampoo, hair styling…

Sustainability: 100% recyclable, PCR is available

Volume size: 100ml(3.33oz)

Contact Us

Contact Us